-

May 24th, 2009, 05:14 PM

#21

Hostboard Member

Re: Horn mouth termination

NICE.

(Could the speaker cable run downinside the metal pipe?)

-

May 24th, 2009, 06:15 PM

#22

Senior Hostboard Member

Re: Horn mouth termination

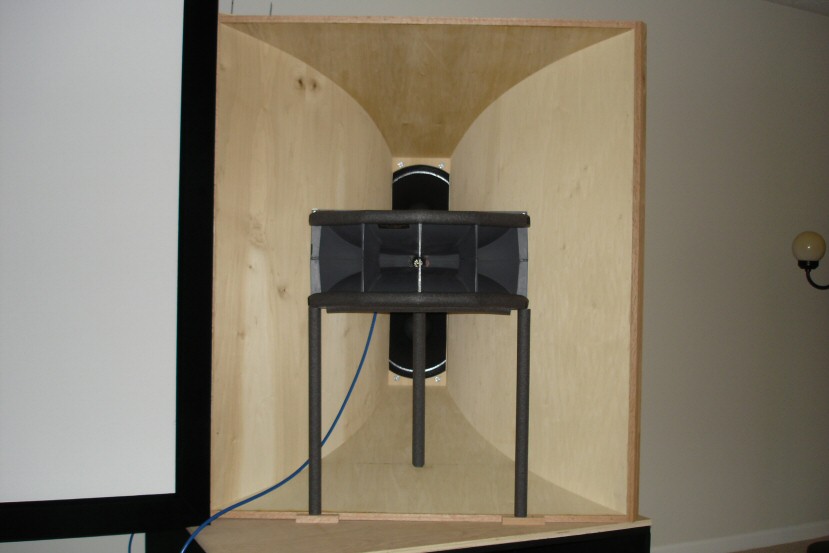

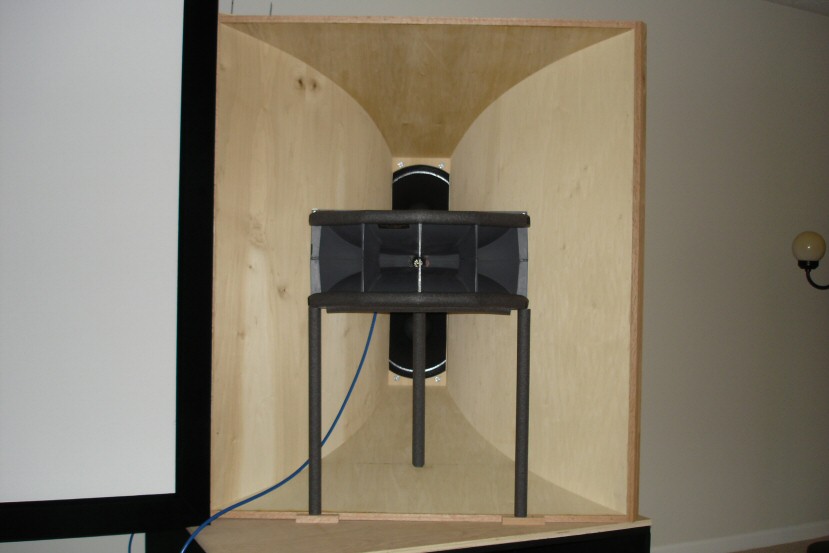

Now, this concept of pipe insulation can be used everywhere in this design. I didn't have enough to cover the top frames or sides but the supports and bottom frames are. What you can't see is I ran strips of batting around the back of the horns and covered it with some black felt and tied it in place. It's starting to look cool too...

-

May 24th, 2009, 06:17 PM

#23

Senior Hostboard Member

Re: Horn mouth termination

Originally Posted by

lowpoke

NICE.

(Could the speaker cable run downinside the metal pipe?)

That's the plan...but I'm going to handle this a bit later...probably during the finishing stage.

full pic:

-

June 3rd, 2009, 09:16 AM

#24

Senior Hostboard Member

Re: Horn Mouth Termination

Thanks to Brad for the pipe-foam idea !

- I did it two different ways on an Emilar EH-500 horn driven by a 288-8K. ( This 2" entry horn is actually a bit smaller than the 811 so I also had to use a 1.4" to 2" adapter made by Selenium ) .

- The foam makes a measurable change ( in some areas ) thats certainly worth the $ 2.00 invested .

- Now having posted the positive / I need to mention a negative which is ;

- The way Steve ( apparently /& please correct me if I'm wrong ) has implemented the foam changes the "Q" of the horn ( with the horn lip inserted into the foam slit ).

- By diminishing ( closing in ) the exit area of the horn bell, the HF is slightly lifted ( above 6K if I remember correctly ) .

- A bit of HF lift is usually a good thing but ;

- The "lift" comes at the expense of inducing a bunch of moderate ( to severe ) periodic comb-filtering .

As bfish mentioned ( & implied ) the better application of the pipe-foam is to slit it in half ( he suggested a filleting knife / I used box cutters successfully ) & then apply the foam onto the leading edge of the horn-bell / more or less creating a continous rounded over extension of the front edge .

- This was all measurable with ARTA ( both the FR & Group Delay responses showed changes ). I didn't save the file / but if I recreate it / I'll post it at LHF & then link into it ( from within this thread ) .

>< cheers Earl K

ps ; though it's still conjecture on my part I did see a change in one area of the GD that might be construed as a reduction in "horn-honk: ,

-

June 3rd, 2009, 09:34 AM

#25

Senior Hostboard Member

Re: Horn mouth termination

Good news! Thanks for that report. If you can get the measurements together, that would be great.

I don't remember having any HF problems on my 811 horns, but could be wrong. When I used towels, they did not roll over into the mouth area but just extended it slightly and rolled it back around smoothly toward the back. It was easy to hear the change with pink noise while placing and removing the towels. Measurements showed a kink at 1Khz that was removed.

I did the pipe foam, too - the way Steve did. It was good, but not as quite as good as the towels. A lot less goofy looking, tho! I think the ideal thing would be to build a sort of wire mesh form around the mouth and stuff/cover it with felt or something. The idea is to easy the transition from the hard horn surface to the air.

-

June 3rd, 2009, 10:59 AM

#26

Senior Hostboard Member

Re: Horn Mouth Termination

Originally Posted by

Earl K

Thanks to Brad for the pipe-foam idea !

- The way Steve ( apparently /& please correct me if I'm wrong ) has implemented the foam changes the "Q" of the horn ( with the horn lip inserted into the foam slit ).

- By diminishing ( closing in ) the exit area of the horn bell, the HF is slightly lifted ( above 6K if I remember correctly ) .

- A bit of HF lift is usually a good thing but ;

- The "lift" comes at the expense of inducing a bunch of moderate ( to severe ) periodic comb-filtering .

Right, this is great information...thanks Earl.

This was the reason I chose the "cheapo" foam for this initial test.

It is much less dense than the industrial grade stuff Brad suggested.

I cannot hear HF lift...not saying it's not there, just cannot hear it.

I can hear dimished honk and coloration.

I will eventually come up with something in keeping with this extension of the bell

into place.

-

June 3rd, 2009, 12:32 PM

#27

Senior Hostboard Member

Re: Horn mouth termination

Originally Posted by

Panomaniac

In this thread

http://www.hostboard.com/forums/alte...ml#post1775827

The idea is to easy the impedance change from the horn mouth to free air. If the change is too abrupt, it causes diffraction artifacts that are audible. Using a lossy material to gradually easy from hard metal to soft air seems to work well.

I will try it of course... but will also pose the question.

Is this approach valid for Manta Ray horns, or is the 'diffraction' that we'd be killing, part of the equation WRT how they actually achieve CD (or otherwise how they work)? Mine happen to be the smaller ones, probably 12" / side, still un-id'd officially.

I may try spray-starch as a reversible way to attach the (foam, felt, whathave you). Unsure of it's effect on paint, so I may test on something similar first.

-

June 3rd, 2009, 12:58 PM

#28

Senior Hostboard Member

Re: Horn mouth termination

Originally Posted by

gearfreak

I will try it of course... but will also pose the question.

Is this approach valid for Manta Ray horns, or is the 'diffraction' that we'd be killing, part of the equation WRT how they actually achieve CD (or otherwise how they work)? Mine happen to be the smaller ones, probably 12" / side, still un-id'd officially.

I may try spray-starch as a reversible way to attach the (foam, felt, whathave you). Unsure of it's effect on paint, so I may test on something similar first.

I plan to use rubber cement for my work.

-

June 3rd, 2009, 01:01 PM

#29

Senior Hostboard Member

Re: Horn mouth termination

Yes, but what about the paint? It seems that anything I used on the 811 horns took off the gold paint.

There are some double face tapes that aren't too bad. Made for photos and such....

-

June 3rd, 2009, 01:50 PM

#30

Senior Hostboard Member

Re: Horn mouth termination

- Here's a look at a repeat study that I ran today for the foam-lips ( above & below the existing metal edge / like Steve implemented ).

- One can see the deepening of the comb-filters that I previously mentioned .

- Red trace in background is the horn without any foam-lips . Purple trace is the same as the blueish white - just lower in level for easy of view .

- Sorry for the washed out colors & contrast / both ARTA & Powerpoint don't handle bmp-jpg exports very well ( IME ) .

>< cheers

ps; please let me know if this image opens for you, due to the fact that I'm hosting it over at LHF .

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

This forum has been viewed: 24589437 times.

Bookmarks